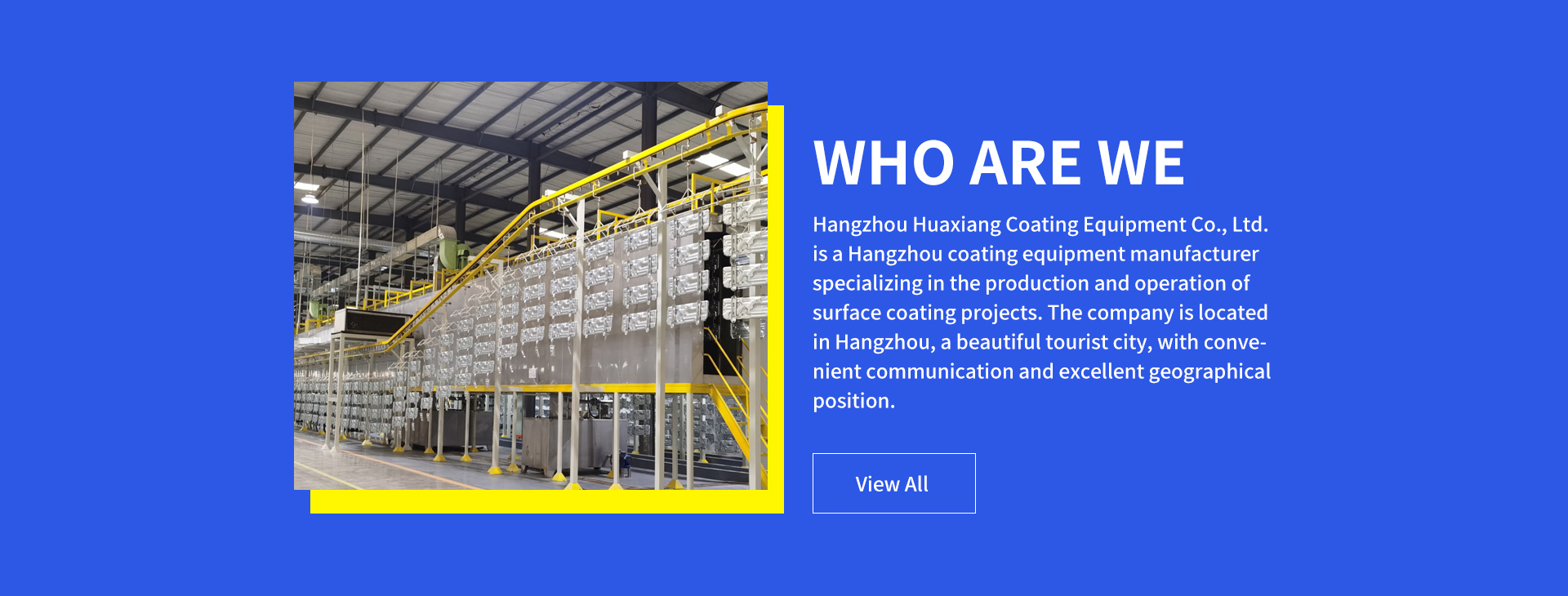

1. Introduction to Industrial Paint Systems

Industrial paint systems are advanced setups designed to apply high-quality, uniform coatings to metal, plastic, and composite surfaces. These systems typically include spray guns, paint booths, curing ovens, conveyor belts, and filtration units. Their precision ensures minimal waste and consistent finishes, making them vital for large-scale manufacturing.

2. Applications of Industrial Paint Systems

Industrial paint systems are widely used in automotive manufacturing (car bodies, parts), aerospace (aircraft components), construction (steel structures), and furniture (metal frames). They are also critical in shipbuilding, electronics, and heavy machinery industries for corrosion resistance and aesthetics.

3. Cost of Industrial Paint Systems

Prices range from 15,000formanualsetupstoover500,000 for automated systems. Factors like automation level (robotic arms), spray technology (electrostatic, airless), and features (climate control) significantly impact costs. Leasing options are available for budget flexibility.

4. How to Use Industrial Paint Systems

Operators must clean surfaces thoroughly, adjust spray pressure for even coverage, and maintain curing temperatures (150–200°C). Regular nozzle cleaning and filter replacements prevent clogs. Automated systems often use programmable controls for repeatable results.

5. Choosing the Best Industrial Paint System

Evaluate production volume, part size, and coating type. High-output facilities need automated systems with robotic arms, while smaller shops may opt for manual models. Prioritize energy efficiency, maintenance costs, and vendor support for long-term value.

6. Safety Tips for Industrial Paint Systems

Ensure proper ventilation to reduce fume exposure. Ground equipment to prevent electrostatic sparks. Operators must wear PPE: respirators, gloves, and flame-resistant clothing. Regularly inspect electrical systems and solvent storage areas.

7. Design Advantages of Industrial Paint Systems

Modern systems focus on energy efficiency, reduced overspray, and modularity. Features like recirculating filters cut paint waste by 40%, while programmable settings adapt to diverse projects, enhancing productivity and sustainability.

8. Q&A on Industrial paint systemss

Q: Which industries use industrial paint systems most?

A: Automotive, aerospace, and construction sectors rely heavily on these systems for durable coatings.

Q: Can these systems handle large components?

A: Yes, conveyorized systems are ideal for large parts like aircraft wings or ship hulls.

Q: Are eco-friendly paints compatible?

A: Yes, water-based and low-VOC paints work with advanced filtration units.

Q: How do robotic arms improve coating quality?

A: Robotic arms ensure precision, reduce labor costs, and minimize human error.

Q: What maintenance extends system life?

A: Clean spray guns weekly, replace filters monthly, and lubricate moving parts quarterly.

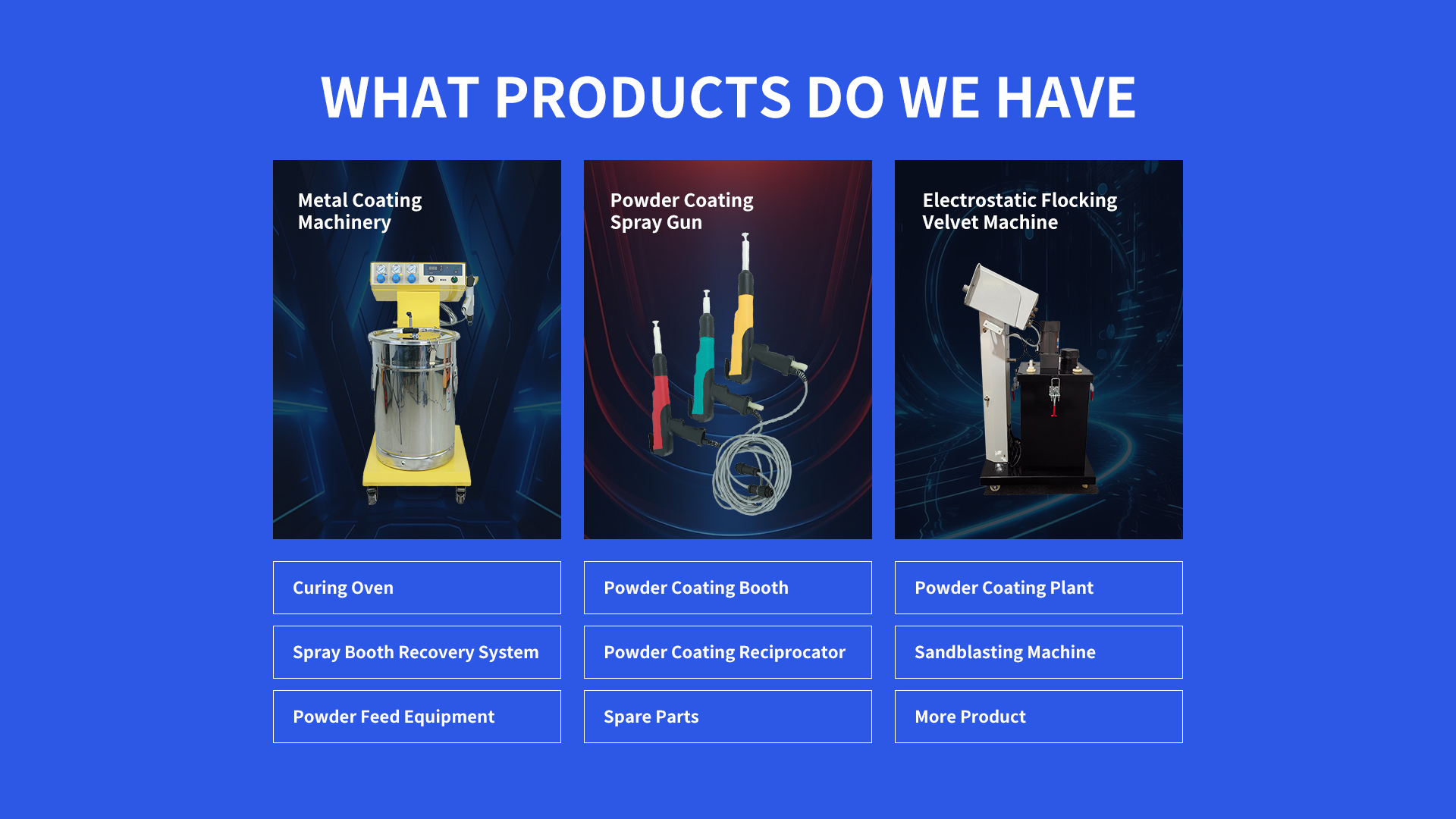

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com